1/2" Exact Temp Valve Filter Screen Cleaning

Preparation:

|

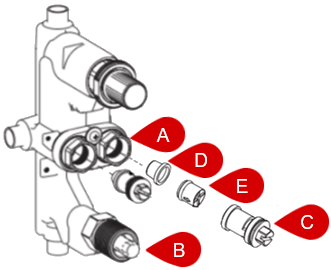

Parts Legend

|

Video: |

Disassembly: |

|

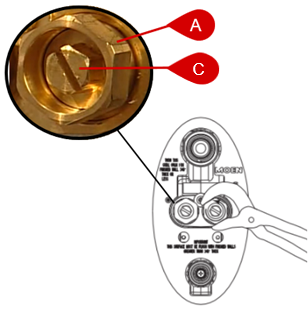

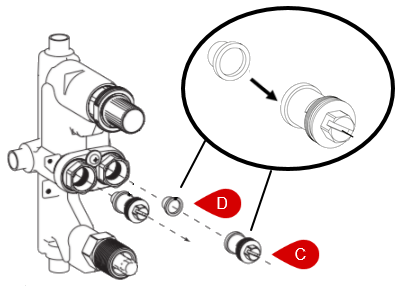

1. Prior to cleaning the filter screens (D), the water supply to the valve body must be shut off. The valve body's internal flow stops are opened and closed by turning the two large (1 1/8") outer hex nuts (A) located in the center of the valve body. Turn off the flow to the valve body by using a wrench to turn each of the large outer hex nuts (A) fully clockwise. To fully shut off the flow, several full turns of each outer hex nut (A) are required. After shutting off the water to the valve body, release any residual water by turning the flow extension (B) fully counterclockwise. 2. The filter screen (D) is located on the back side of the check valve assembly (C). To remove the check valve assembly (C), position a wrench on the large outer hex nut (A) and hold it stationary. Use a flathead screwdriver in the slot in the center of the check valve assembly (C) and unthread counter-clockwise until it comes out. |

Cleaning the Filter Screen: |

|

|

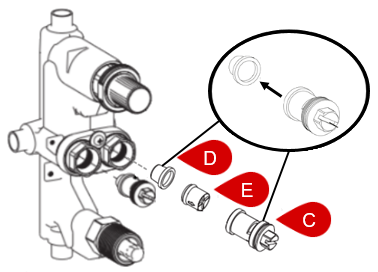

3. Remove the filter screen (D) by sliding it off the back side of the check valve assembly (C). If the filter screen (D) did not come out with the check valve assembly (C), use tweezers or needle-nose pliers to pull it out of the opening that the check valve assembly (C) was removed from. Clean any debris from the filter screens (D) by rinsing them with water. Confirm the check valve assembly (C) is operating properly by holding it with the non-metallic white check valve (E) facing upwards. Using a flathead screwdriver, gently press push down on the rubber diaphragm in the center and observe if it springs back up. If it is operating properly, it should push in when you press on it and will spring back when you stop pressing on it.

|

Flush the Valve Body: |

|

|

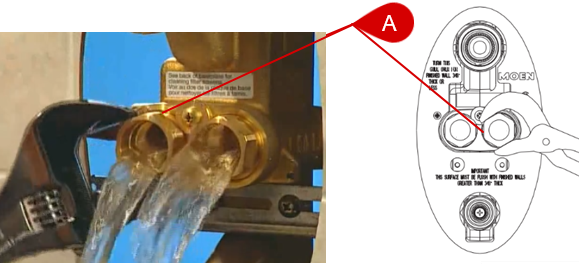

4. Flushing the valve body eliminates any loose debris that may have accumulated inside the valve body. To clear the system, water will need to be forced through the brass valve body. To flush the valve body, turn the water on by using a wrench to slightly rotate one of the large (1 1/8") outer hex nuts (A) counter-clockwise. Turn the water back off by using a wrench to rotate the large (1 1/8") outer hex nuts (A) fully clockwise. Repeat this process for the second large (1 1/8") outer hex nut (A). |

Assembly: |

|

|

5. Attach the filter screen (D) to the check valve assembly (C) by sliding the large opening of filter screen (D) onto the raised edge on the back of the check valve assembly (C). Reinstall the check valve assembly (C) by using a flathead screwdriver in the slot in the center of the check valve assembly (C) and thread it clockwise into the valve body until tight. Turn on the flow to the valve body by using a wrench to turn each of the outer hex nuts (A) fully counter-clockwise. To fully turn on the flow, several full turns of each outer hex nut (A) are required. |

For additional information on 1/2" Exact Temp products visit Shower Handle: 1/2" Exact Temp at solutions.moen.com.

Still Not Finding What You're Looking For?

Contact Us or Call 1-800-BUY-MOEN

Non US? Moen Canada | Other International Sites